厂房厂貌

Plant Photos

厂房厂貌

Plant Photos

Nantong New Facility

(InvisPower Industrial Park) Phase I Project was put into production on January

27, 2019, covering an area of 50 mu, with a total planned floor area of 60,000 m2.

Plant No. 1 has been equipped with 2 SMT lines, 1 selective welding line, and 2

fully automated assembly and testing lines; with 4 modular SMT lines, 3

selective welding lines and 6 automated assembly lines planned to put into

operation; and with an estimated annual output of 6 million sets of automotive

wireless charging, NFC, USB and other automotive electronic products. In

addition, Nantong New Facility Phase I Project also set up a 500 m2 reliability

laboratory and a laboratory for research and development of new energy vehicle

wireless charging.

-

Nantong New Facility

Nantong New Facility Phase I Project was put into production on January 27, 2019, covering an area of 50 mu, with a total planned floor area of 60,000 m2; it has been equipped with 2 SMT lines, 1 selective welding line, and 2 fully automated assembly and testing lines; with 4 modular SMT lines, 3 se

-

Advanced Modern Manufacturing Systems

AGV automatic loading

AES auxiliary material traceability system

MES auxiliary material/quality traceability system

JES tooling/steel mesh/equipment system

HES job training arrangement system

EES ESD online monitoring system

TES temperature and humidity monitoring system

-

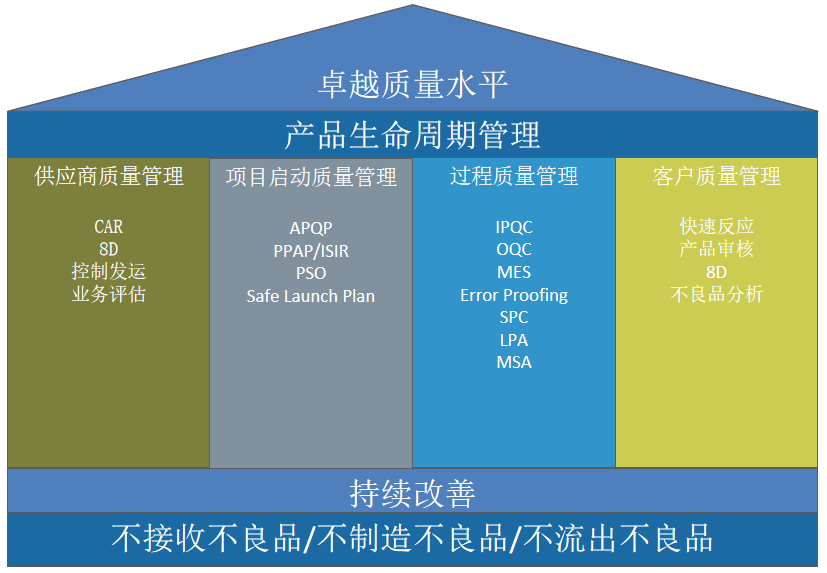

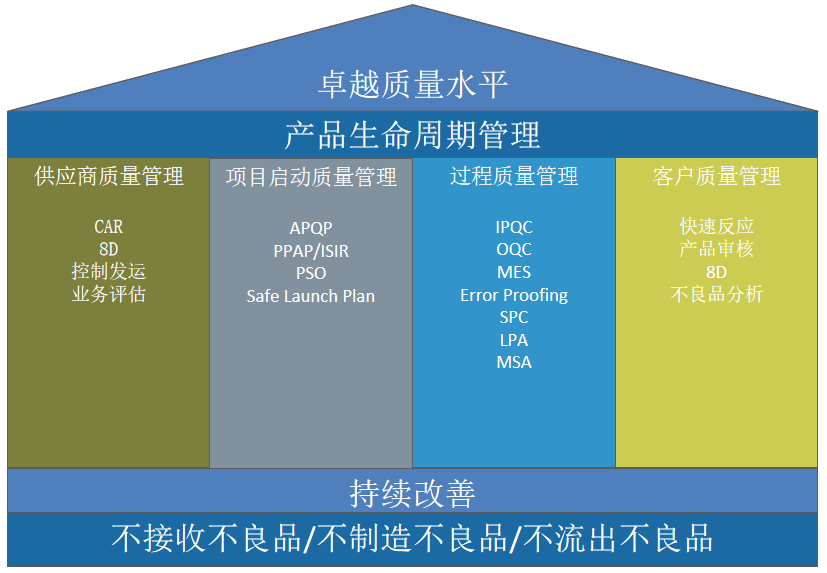

QC

Win customer satisfaction through the following methods:

Rigorous project execution Reduced COPQ Pursuit of zero defects Improved employees’ skills and sense of responsibility

研发中心及实验室

R&d center and laboratory

研发中心及实验室

R&d center and laboratory

Nantong New Facility Phase I

Project was put into production on January 27, 2019, covering an area of 50 mu,

with a total planned floor area of 60,000 m2; it has been equipped

with 2 SMT lines, 1 selective welding line, and 2 fully automated assembly and

testing lines; with 4 modular SMT lines, 3 selective welding lines and 6

automated assembly lines planned to put into operation; and with an estimated

annual output of 6 million sets of automotive wireless charging, NFC, USB and

other automotive electronic products. In addition, it also set up a 500 m2 reliability laboratory and a laboratory for research and development of new

energy vehicle wireless charging.